Basic Hydraulic Theory

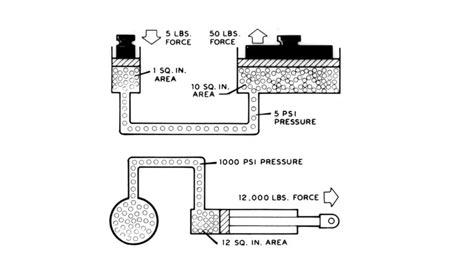

The basis for all hydraulic systems is expressed by Pascal's law which states that the pressure exerted anywhere upon an enclosed liquid is transmitted undiminished, in all directions, to the interior of the container. This principle allows large forces to be generated with relatively little effort. As illustrated, a 5 pound force exerted against a 1 inch square area creates an internal pressure of 5 psi. This pressure, acting against the 10 square inch area develops 50 pounds of force.

In a basic hydraulic circuit, the force exerted by a cylinder is dependent upon the cylinder bore size and the pump pressure. (There is no force generated unless there is resistance to the movement of the piston). With 1000 psi pump pressure exerted against a 12 square inch piston area (approximately 4" dia.), a force of 12,000 pounds is developed by the cylinder. The speed at which the piston will move is dependent upon the flow rate (gpm) from the pump and the cylinder area. Hence, if pump delivery is 1 gallon per minute (231 cu.in./min.) the cylinder piston will move at the rate of 20 in./min. (231cu.in. ÷ 12cu.in./min.).

The simplest hydraulic circuit consists of a reservoir, pump, relief valve, 3-way directional control valve, single acting cylinder, connectors and lines. This system is used where the cylinder piston is returned by mechanical force. With the control valve in neutral, pump flow passes through the valve and back to the reservoir. With the valve shifted, oil is directed to the piston side of the cylinder, causing the piston to move, extending the rod. If the valve is returned to neutral , the oil is trapped in the cylinder, holding it in a fixed position , while pump flow is returned to the reservoir. Shifting the valve in the opposite direction permits the oil to pass through the valve back to the reservoir. The relief valve limits the system pressure to a pre-set amount. Relief valves are commonly incorporated into the directional control valve.

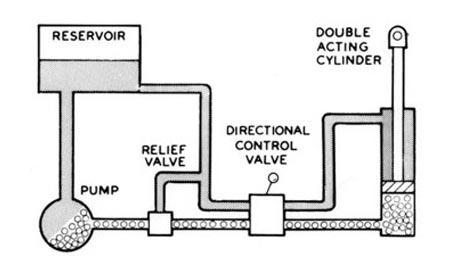

A hydraulic system using a double acting cylinder and a 4-way valve differs from the single acting cylinder system in that the cylinder can exert force in both directions. With the control valve in, neutral flow is returned to the reservoir. When shifted in one direction , oil is directed to the piston side of the cylinder, causing the cylinder to extend. Oil from the rod side passes through the valve back to the reservoir. If the valve is shifted to neutral , oil in the cylinder is trapped, holding it in a fixed position. When the valve is shifted in the opposite position, oil is directed to the rod side of the cylinder, causing the cylinder to retract. Oil from the piston side passes through the valve back to the reservoir. Cylinder extend force is the result of the pressure (psi) times the piston area (minus any force resulting from the pressure acting against the rod side of the piston). Retract force is a result of the pressure (psi) times the area difference between the rod and the piston (minus any force resulting from pressure acting against the piston side of the cylinder).

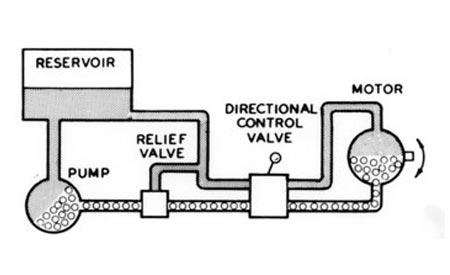

Rotary hydraulic motor circuits are basically the same as cylinder circuits. Systems may be uni-directional or bi-directional (as shown). The amount of rotary force (torque) available from the motor is a function of pressure (psi) and motor size. Speed is a function of flow and motor size. All of the systems described above are open center systems due to the oil flowing through the control valve back to the tank. Most systems are this type. Closed center systems use control valves with the inlet port blocked and variable displacement pumps. With the control valve in neutral , the pump is "de-stroked" to zero flow.