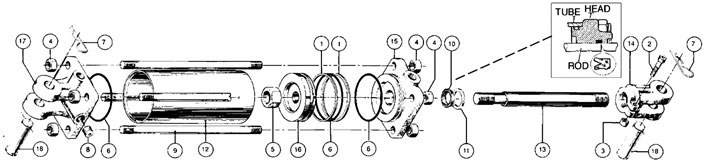

Seal Replacement for DB, DE and DU Cylinders

- Remove all port obstructions and make sure all oil has been drained from the cylinder.

- Clamp rod end mount (14) in vise and fully extend cylinder. If there is no mount, protect rod threads while clamping.

- Remove the four tie bolt nuts (4) on head end and pull out the tie bolts from the base end.

- Remove the base (17) and slip the tube off of the head (15). If necessary, gently tap the head and base with a rubber mallet to loosen.

- Remove piston nut and slip piston (16) and head off rod (13). Drive piston off with head.

- Remove old seals from head, piston and base.

- Wash and check all parts for excessive wear or obvious defect which might interfere with operation.

- Lubricate all new seals with STP or heavy oil before assembling.

- Install new seals (6)(10) and (11) in head taking care to position the I.D. U-cup (10) as shown. To install the wiper (11), place a thin, flat piece of metal against it & tap into place. Be sure the wiper is positioned squarely & evenly in the groove with lip facing out as shown.

- Install O-ring (6) and back-ups (1) on piston as indicated.

- Install O-ring (6) on the base.

- With a twisting motion push head onto rod. Apply a few drops of loctite #277 to piston rod shoulder and reassemble piston onto rod.

- Torque piston nut according to table #1. Lube head & piston seals.

- Slide tube over piston and onto head. Replace base making sure parts are properly aligned to avoid cutting O-rings.

- Replace tie rods and torque nuts as specified in table #2.

- Hand stroke cylinder to check for binding.

- Your cylinder is now ready for operation.

Cross Manufacturing Inc. assumes no responsibility for future malfunctions of or damage to equipment including parts if above procedures are not followed.